Malfunctions and maintenance methods of pathological tissue dehydrator

时间:2023-10-28

With the rapid development of medical technology, pathological tissue dehydrators have become one of the necessary large-scale instruments in the daily tissue processing work of the pathology department in every large and medium-sized hospital. Pathological tissue dehydration machines can be divided into two categories based on their design principles: rotary and fully enclosed. Due to different working principles, the two types of tissue dehydrators have different common faults and maintenance methods in use. Mastering the knowledge of using and maintaining dehydrating instruments is particularly important for ensuring the smooth progress of daily work. This article analyzes the common faults of two types of tissue dehydrators and their respective maintenance methods.

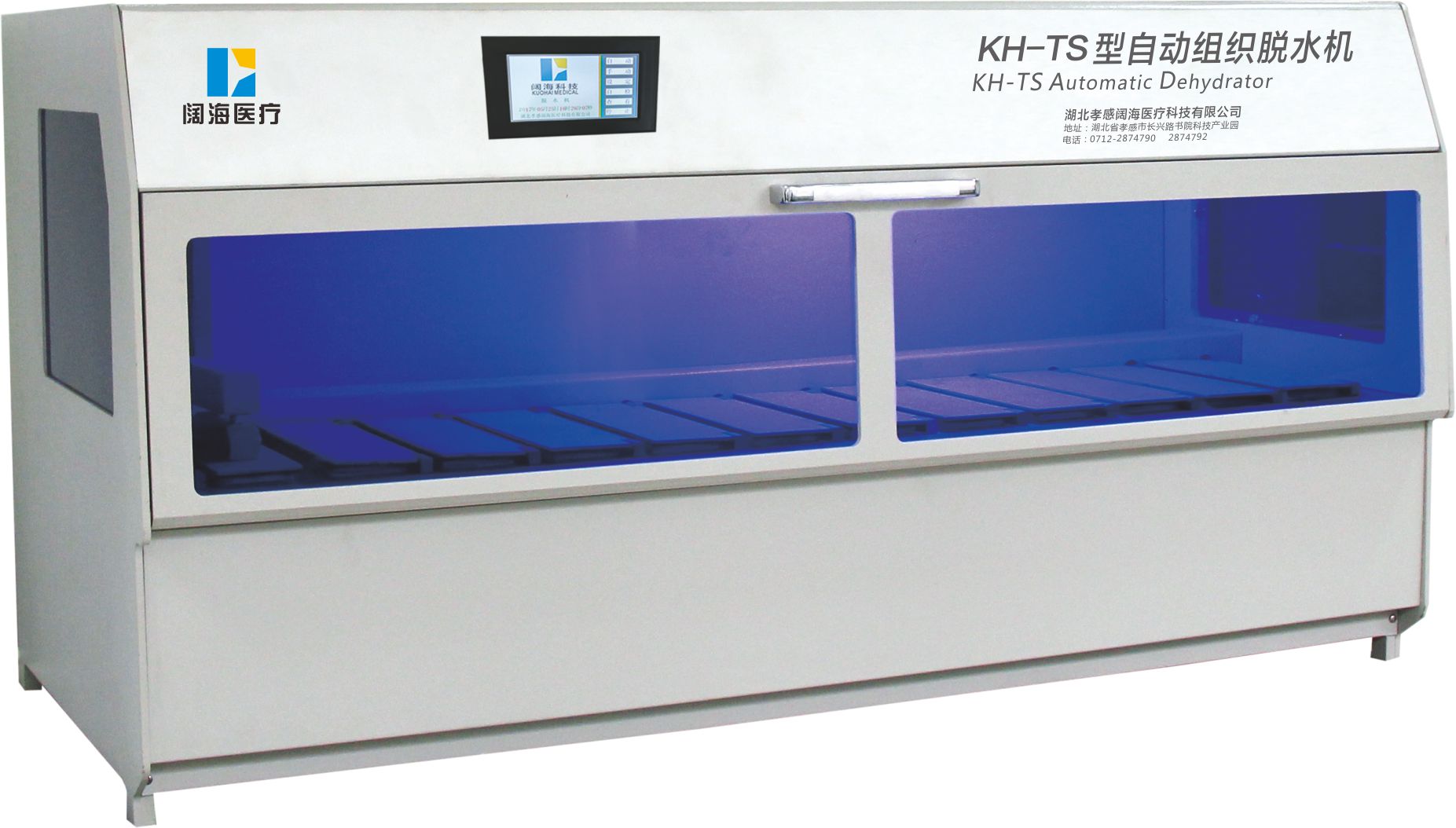

KH-TS intelligent automatic dehydration machine for biological tissues

1. Basic concepts

1.1 Working principle of pathological tissue dehydrator

By soaking different reagents and reagents with different concentration gradients, the intracellular and intercellular water of biological tissues is extracted to achieve dehydration. Finally, the dehydrated tissue is immersed in paraffin and taken out together.

1.2 Classification of pathological tissue dehydrators

The first type of reagent tank is fixed, and the tissue specimen basket is mechanically moved into different reagent tanks to soak in sequence until the tissue dehydration is completed. This type of dehydrator is collectively referred to as a rotary dehydrator; The second type of dehydration tank for storing tissues is fixed, and reagents are pumped into the dehydration tank in a predetermined sequence through computer system control for dehydration. This type of dehydration machine is collectively referred to as a fully automatic closed dehydration machine.

2. Different faults and maintenance methods of two types of pathological tissue dehydrators

2.1 Rotary pathological tissue dehydrator

2.1.1 Common Fault Analysis

The most common malfunction of a rotary pathological tissue dehydrator is the "jamming cylinder", which means that during the process of suspending and moving the tissue specimen basket, the mechanical arm fails to immerse the tissue in the reagent due to various reasons, resulting in tissue dehydration failure. There may be multiple reasons for "jamming", which can be roughly classified into the following categories:

① Due to human factors, the hanging tissue specimen basket was not in place. During the descent process, the tissue specimen basket touched the reagent cylinder wall and could not be fully immersed in the reagent cylinder due to resistance.

② The sensor and circuit that controls the movement of the robotic arm have malfunctioned, unable to provide correct indication signals to the robotic arm.

③ The internal structure of the robotic arm undergoes displacement deformation due to external forces and other factors.

2.1.2 Maintenance methods

Firstly, it is necessary to check whether the tissue specimen basket is hanging crooked or if the reagent tank is displaced due to other factors; After excluding human factors, open the inside of the robotic arm to observe whether there is obvious resistance. If there is indeed resistance inside the robotic arm, adjust it according to the principle of the robotic arm's own cylinder movement; After troubleshooting the mechanical arm itself, it was confirmed whether the circuit board and sensor were malfunctioning.

2.2 Fully automatic closed pathological tissue dehydrator

2.2.1 Common Fault Analysis

The fully automatic closed tissue dehydrator, due to its high level of intelligence, low volatility of reagents, large volume of processed tissue samples, and multiple selection functions during the dehydration process, such as how to pressurize, zero empty, and warm, has been favored by the majority of pathology department teachers. Its common faults are more complex than rotary tissue dehydrators, and can be summarized as follows:

① Generally, pipeline drainage reagents are used. When there are many impurities mixed in the reagents, the pipeline will be blocked during the drainage of the reagents, and the probability of such failures will increase in winter.

② Insufficient vacuum pressure or pressure during reagent extraction, unable to continue normal dehydration.

③ Touch screen black or blue.

④ Air leakage in the dehydration tank of the organization.

⑤ Unable to extract paraffin.

⑥ Dehydration cylinder probe alarm error.

⑦ When running the cleaning program, the alarm level of the dehydration cylinder is insufficient.

⑧ The tissue specimen is too brittle after dehydration.

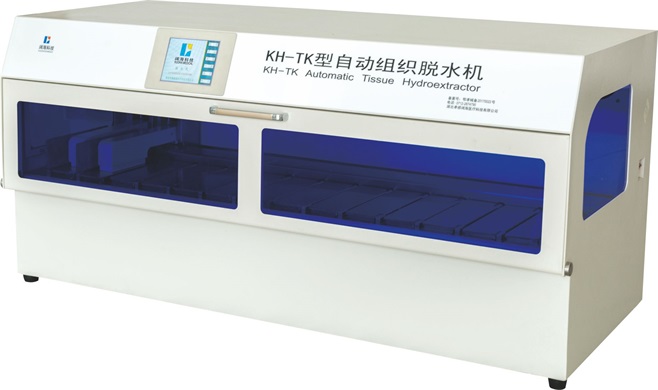

KH-TK Biological Tissue Intelligent Dehydrator

2.2.2 Maintenance methods

① Firstly, it is necessary to keep the cleaning solution clean, so that the dehydration tank can be cleaned thoroughly and paraffin containing impurities will not be carried into the pipeline and reagent bottle; Secondly, the dehydration reagent should also be kept clean, and the mixture of tissue fat and paraffin in the reagent is also one of the main reasons for pipeline blockage; Finally, it is also possible that due to misoperation, the partially drained paraffin in the dehydration tank flowed into the common pipeline through which the reagent passed, causing the paraffin to solidify and cause blockage in the pipeline. There are various methods to deal with pipeline blockage, such as airflow blowing method, hot water injection method, and so on.

② If the vacuum pressure or pressure is insufficient, it is necessary to test the functional indicators of the pump first. If it is normal, it may be due to one or more valves in the control gas circuit malfunctioning, usually due to foreign objects inside the valve, which makes the valve unable to work properly. The solution is to open the valve for cleaning; If the pump is not working properly, a new pump needs to be replaced.

③ There are many reasons for the black or blue screen on the touch screen. The repair solution is to shut down for a while and then restart to observe. If the work interface still cannot be opened, it may be due to damage to the hard drive or loss of files that cannot be restored. Replacing the hard drive with a new one can solve the problem.

④ The reason for the leakage of the organizational dehydration cylinder is that there is too much residual paraffin in the sealing ring. Relevant solvents can be used to clean the sealing ring. If the cleaning effect is still not obvious, the sealing ring should be replaced.

⑤ The reason why paraffin cannot be extracted is because there are too many impurities in the paraffin, which can cause blockage in the paraffin channel and valve. Use relevant solvents for cleaning.

⑥ The reason for the alarm error of the dehydration cylinder probe may be due to low reagent purity and high impurities. Firstly, check the cleanliness of the reagent. If it is not caused by the reagent, use xylene to wipe the probe. If the problem is still unresolved, it may be due to a malfunction of the probe sensor and should be replaced.

⑦ The reason for the insufficient alarm liquid level in the dehydration tank is that the cleaning solution loses and evaporates quickly. The solution is to add relevant reagents.

⑧ The reason for the brittleness of tissue samples after dehydration is generally not caused by a malfunction of the dehydration machine. Simply shorten the soaking time of xylene in the dehydration process.

Pathological tissue dehydration machine malfunctions are ever-changing, but if you understand the basic principles of dehydration machine operation, you can easily find the cause of the malfunction and eliminate it.

- 上一篇:Preparation of pathological sections

- 下一篇:没有了!

鄂公网安备42090202000178号

鄂公网安备42090202000178号