How to choose a biological tissue automatic embedding machine?

Time:2023-10-28

The embedding machine is one of the equipment used to prepare for slicing. The function of the embedding machine is to melt paraffin into a liquid state and wrap the processed tissue in it for slicing by the slicing machine. Based on the market situation, there are some issues with some manufacturers' embedding machines. We hope that pathological staff and equipment departments can pay attention to the selection of embedding machines

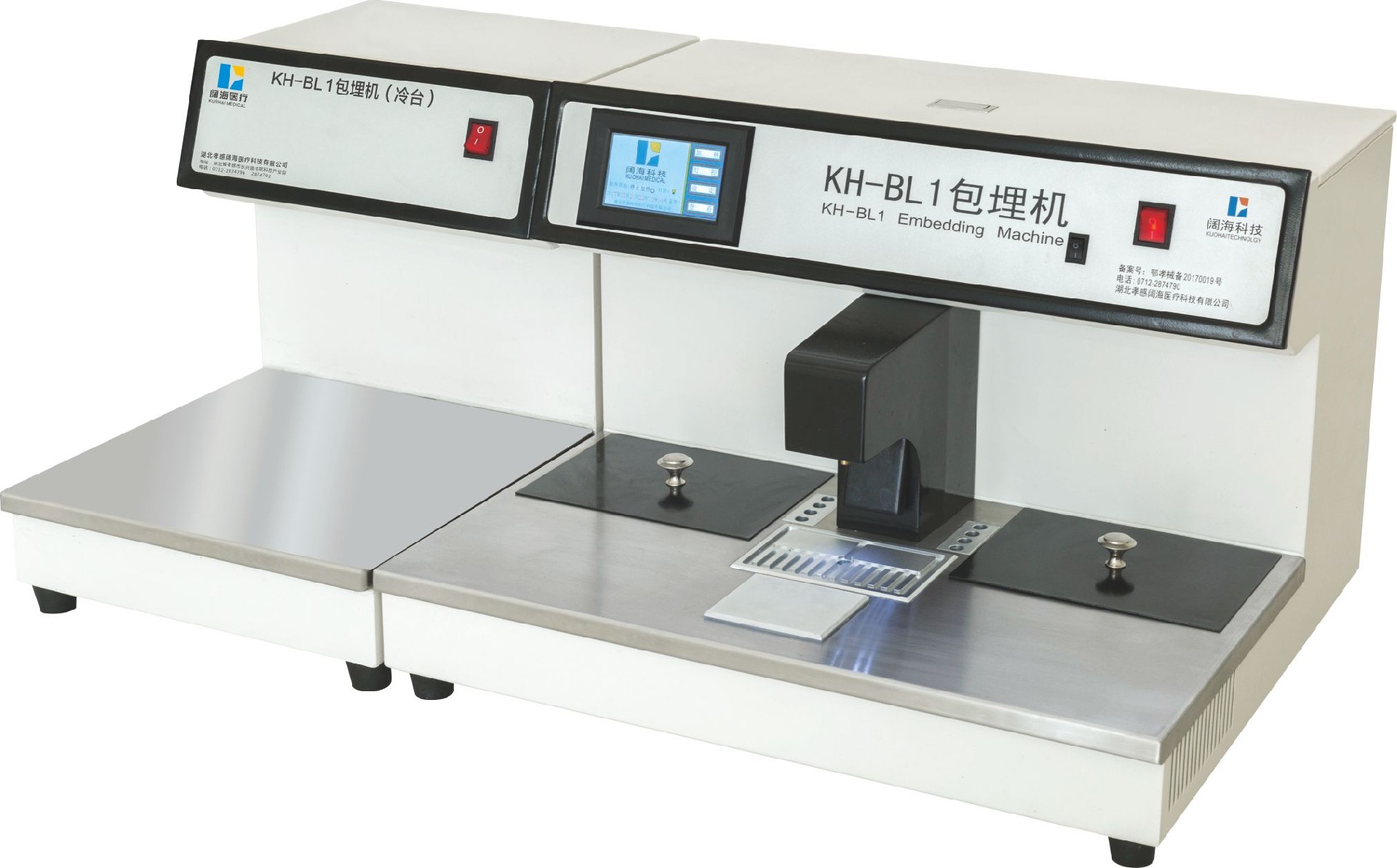

KH-BL1 biological tissue automatic embedding machine

1、 Wax leakage or excessive wax flow - There are many reasons for wax leakage, and two main factors are the key factors that cause wax leakage:

(1) The manufacturer's testing method is incorrect. There is a situation of faulty welding in the main wax cylinder welding, and diesel or liquid paraffin should be used for testing. Water testing usually cannot detect faulty welding points, which can lead to normal water testing and leakage of wax when paraffin is added. In terms of physical properties, the permeability of paraffin is 8.5 times stronger than that of water! Some businesses use basic water testing because it is cheap and effortless. It's not that domestically produced products don't work, but that some merchants have incorrect testing methods.

(2) The sealing of the inlet of the solenoid valve and the temperature probe of the temperature sensor on the main wax cylinder is not good. Most manufacturers only add a rubber pad to think it can block the penetration of paraffin, but they did not expect that rubber will tear the rubber sealing ring when the nut rotates and applies force. The torn rubber ring cannot leak wax. Based on commercial technology considerations, we cannot elaborate on the materials and methods used by Kuaohai Company in this regard. Please forgive me!

(3) Wax shedding is not only like a man with a severe prostate condition, but also very annoying. The reason for excessive wax flow is due to the use of a low-quality solenoid valve, which cannot be fully closed after power failure, resulting in excessive wax flow; Another situation is that impurities in paraffin hinder the normal closing of the solenoid valve. This situation can be basically solved by selecting high-quality solenoid valves and adding a secondary paraffin precipitation filtration function.

2、 Small capacity. Small capacity embedding machines may experience cracking of wax blocks during slicing, and if cracking occurs, they must be re embedded. This is a manifestation of poor toughness of paraffin wax. Previously, beeswax was added to paraffin wax to improve its toughness. Experiments have shown that paraffin wax can also improve its toughness after repeated heating. As the capacity of the embedding machine increases, the remaining paraffin wax will be heated again to melt, and after several repetitions, the toughness of paraffin wax can be improved, So there's no need to add beeswax. The embedding machine of Kuohai Company adopts the world's largest capacity design, with a maximum capacity of 9500 milliliters, which effectively solves the problem of wax cracking.

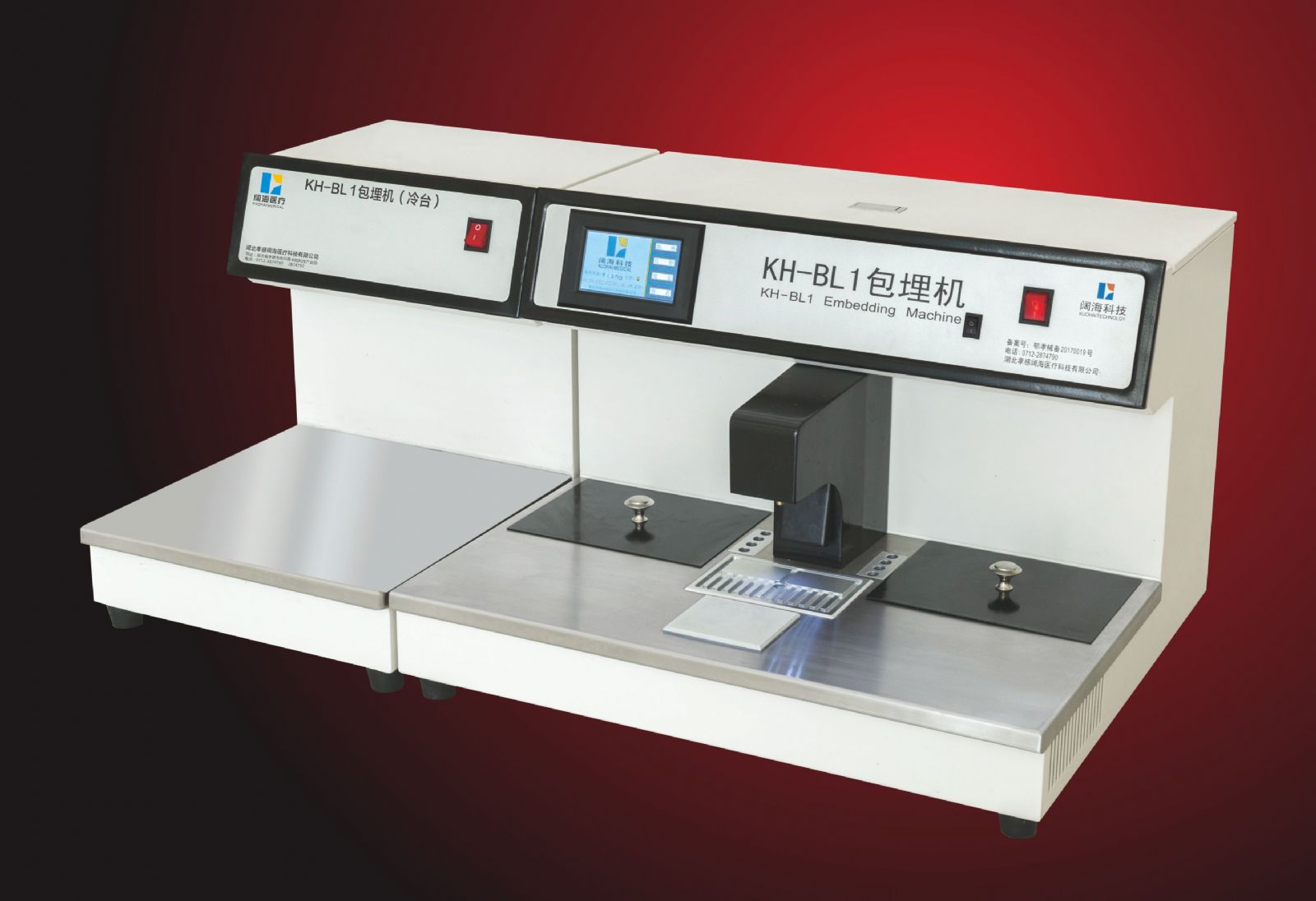

KH-BL1 biological tissue automatic embedding machine

3、 The embedding machine caught fire. The fire in the embedding machine is mainly caused by wax leakage and relay opening and closing. The contact of the relay will automatically open when the temperature reaches the set temperature, and will close again when the temperature drops below the set temperature. At this time, the paraffin temperature is generally above 60 ℃, and there will be electric sparks at the relay contact point when it is closed. If the leaked paraffin drops near the relay, it is very easy to cause a fire! Therefore, it is recommended to purchase embedding machines with contactless heating technology for safety.

4、 The workbench is hot to the touch. This is a manifestation of inhumanity in product design for some products (including imported products). Especially in summer, technicians have to be cautious about embedding. The heating device of the workbench should be in a closed state during operation, and it should be warmed up after the embedding work is completed to melt the residual paraffin on the workbench and automatically recover it.

鄂公网安备42090202000178号

鄂公网安备42090202000178号